Trenching

Automate DC and AC Excavation

Break New Ground

The most advanced technology ever put on an excavator. Period. Using best-in-class sensors, software, and safety, Built engineers have developed a robust trenching solution that is designed to take a beating on any jobsite — and keep running like clockwork.

The Flat-Out Best Way to Dig a Trench

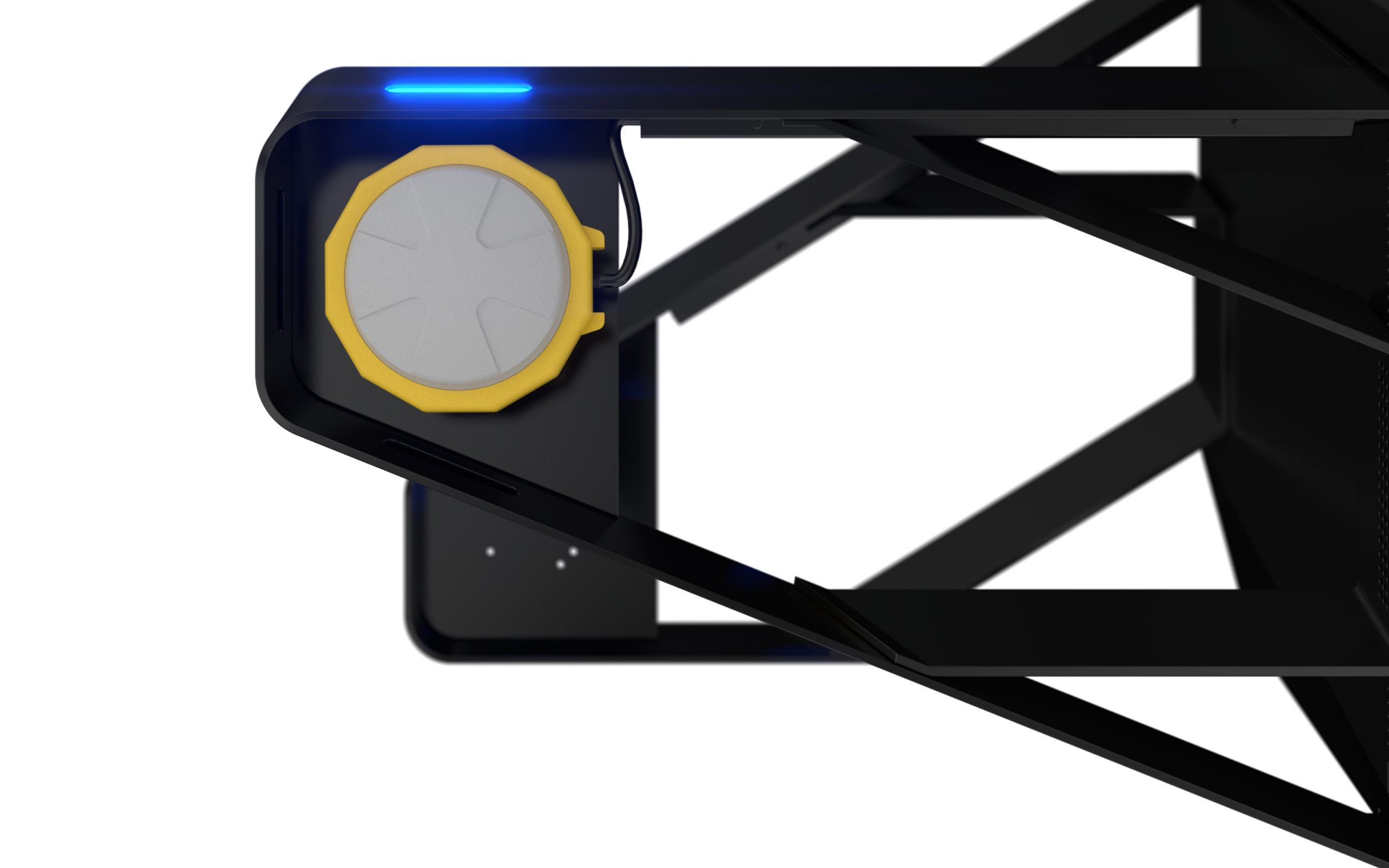

Rugged hardware. Powerful computing. Made for the demands of solar. The world’s first and only aftermarket upgrade, the Exosystem™, installs on the tail of any modern excavator to enable fully autonomous trenching. Preserve manual operation with a versatile mounting system that can be detached when needed.

180 feet per hour

0.1 foot

10%

Hit Record Production Rates

For every gigawatt of PV solar capacity that comes online, contractors need an advanced, cost-effective tool to fast-track DC and AC excavation. Efficiently install more resilient buried infrastructure while reducing costs and rework.

Eliminate Safety Hazards

Take operators out of harm’s way. An 8-Layer Safety System employs a robust, multi-layer system to ensure all corners of the jobsite are safe to work in.

Risk-Free Use

The Exosystem autonomous upgrade installs in less than a day and is fully reversible. The excavator maintains manual operation and any added components do not exceed height limitations for interstate transport.

Smooth Trench Floors

Synthesizing sensor data allows Built’s trenching robot to move in the most precise ways possible. The end result: smooth floors, clean walls, sharp edges, and even spoils to make laying infrastructure inside hassle-free.

Record-High Production Rates

Put the robots to work and mobilize your most valuable workforce to other critical tasks. Robotics keep jobsites running smoothly so you can streamline critical paths and deliver the results needed to win.

Improve Equipment Utilization

Minimize downtime to maximize uptime. Leveraging autonomy streamlines your critical path and keeps your most skilled operators working on the highest level tasks.

One Size Digs All

Mixed fleets are our specialty. The Exosystem is engineered to be compatible with mid-size excavators from all of the leading manufacturers. Built has designed a seamless installation that takes only a few hours and is fully reversible.

Features to Dig Into

Restored Schedule Certainty

Regain control of your schedule. Reduce site congestion and protect the critical path. Spoil piles are sized and spaced evenly, streamlining the workflow of your backfill and compaction crews.

1/10 of a Foot Accuracy

Eliminate rework with accurate depths within 1/10 of a foot. State-of-the-art RTK GPS, IMUs, and proprietary kinematic software enable you to hit the most demanding tolerances.

Real-Time Updates

Get reliable production data delivered to you instantaneously. Using robots gets project teams the visibility they need to manage schedules and resources with zero extra effort.

Automatic As-Builts

Generate as-builts on the fly. Save your surveyors time. Robots can self-survey and automatically produce as-built files so you don’t have to survey trench locations after excavation has taken place.

Custom Trench Widths

Bring your own bucket. Our proprietary software, Everest, supports custom buckets you can measure, upload, and store — even update measurements as teeth wear down.

10% Maximum Grade

A field-proven force multiplier, the robot is equipped to operate in rugged, greenfield locations. It can handle various terrain in grades up to 10% with extreme accuracy.

Flexible Installation

Install with commons tools and simple methods. Built’s Exosystem includes mounting hardware built-in to allow lifting with service trucks, forklifts, or other excavators.

Overtime Digging

Unlock double or triple shift capacity on any jobsite. Fully autonomous trenching robots can take over and continue working when crews are finished to yield higher production rates.

15–50 Ton Machines

This robot plays well with others. Our upgrade kit, the Exosystem, can be installed on most modern excavators from leading manufacturers in less than a day.