Solar Piling

Drive Results by Automating Pile Installs

All Gain. No Pain.

Piling is demanding, and traditional means and methods are being pushed to their limits. Built engineers have spent thousands of hours developing an advanced autonomous solution that can rise to meet the challenges of utility-scale solar.

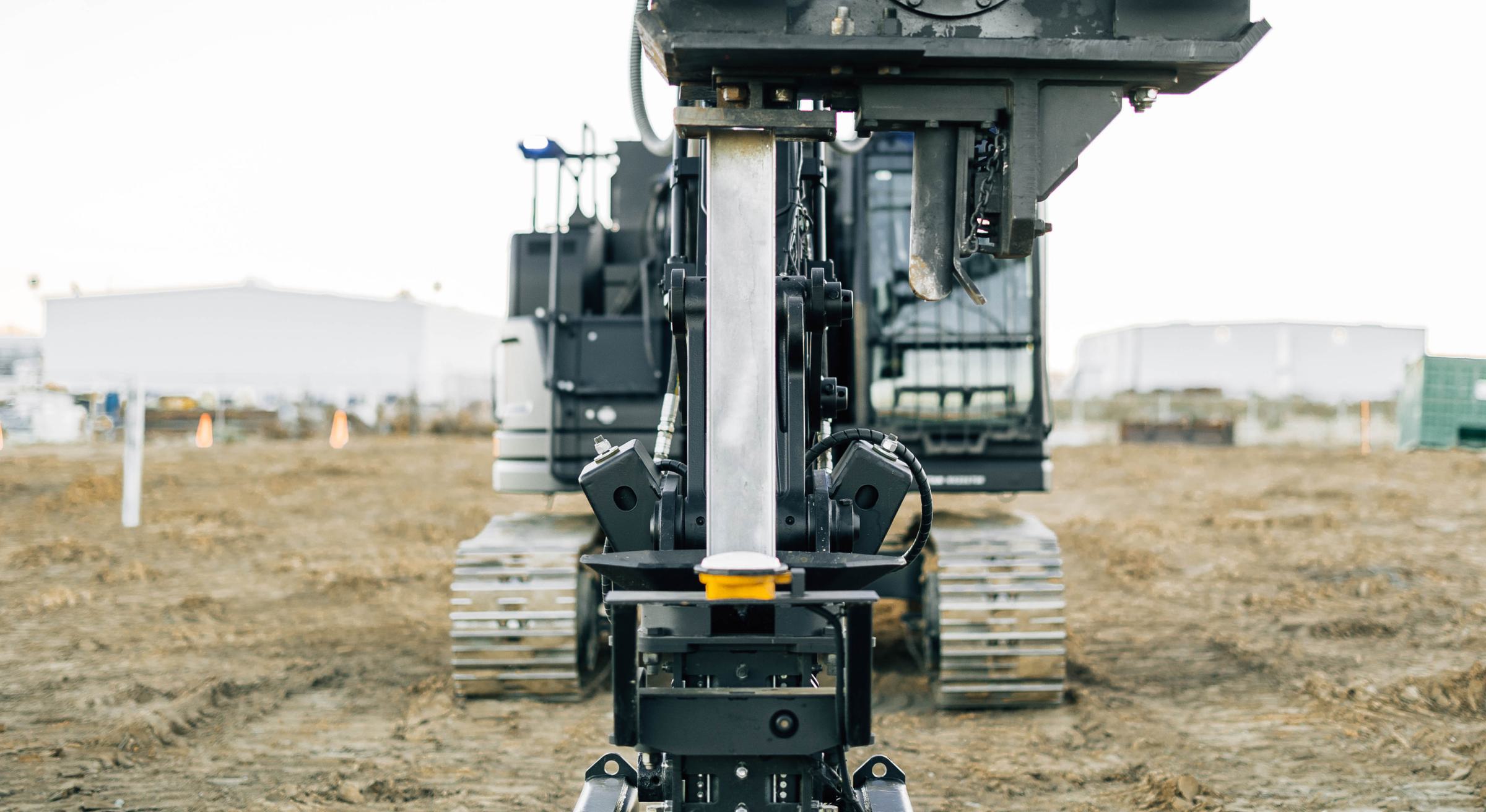

The Bold Standard: The RPD 35

Don’t compromise on your tools. The RPD 35 is a fully autonomous robotic pile driver that combines four steps — surveying, pile distribution, pile driving, and data collection — into a single robot. Take advantage of the superior production and efficiency gains that only a robot can deliver, and outshine the competition.

40,000 lbs

224 piles

10%

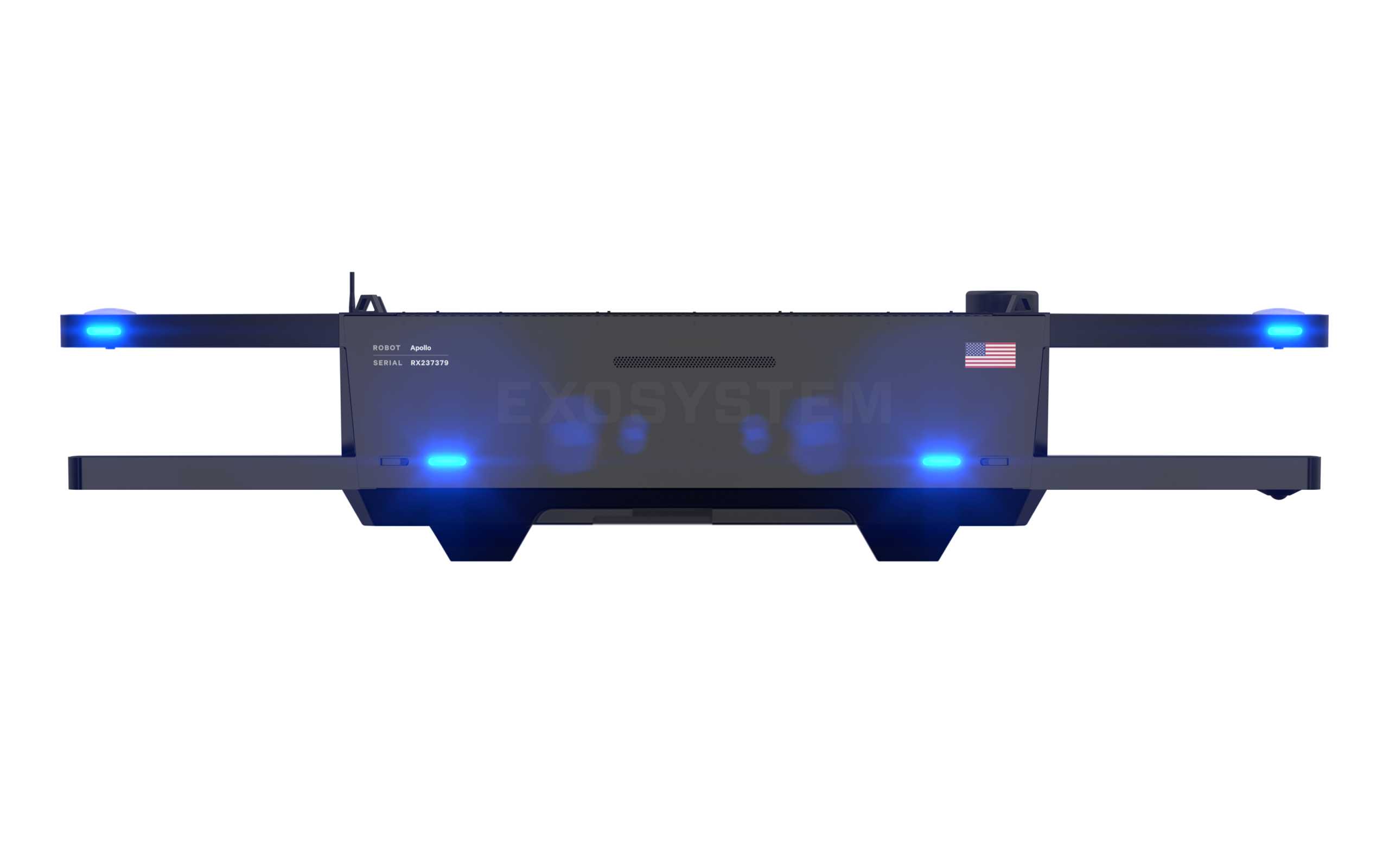

A Powerful Sidekick: The RPS 25

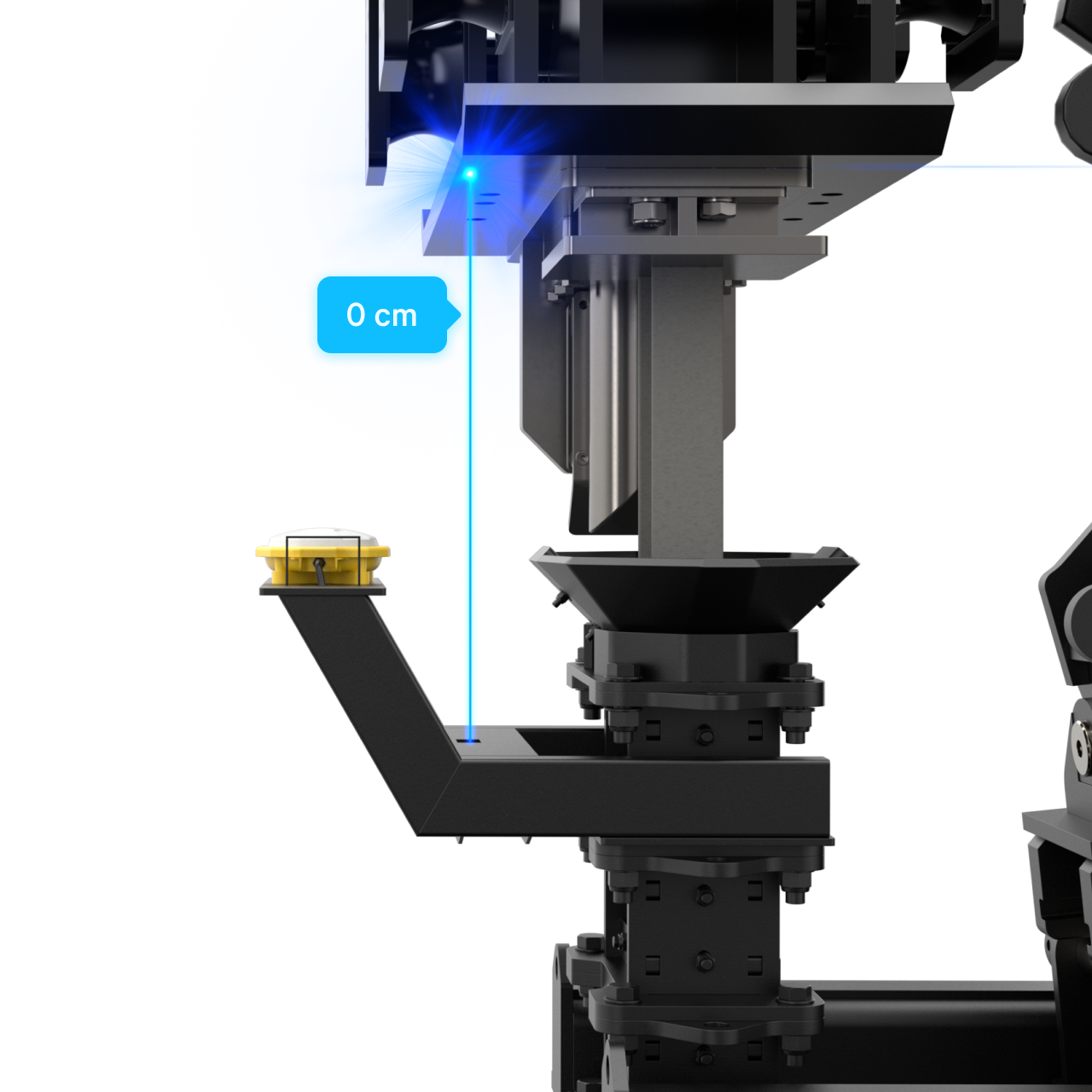

Every RPD 35 pairs with an RPS 25. The robotic pile stabilizer ensures driven piles exceed the most stringent tracker tolerances and produce consistently placed piles every time: accurate z-heights, perfect plumbness, and unrotated piles.

Up to 17 mm

Up to 30 mm

W6×7 to W8×28

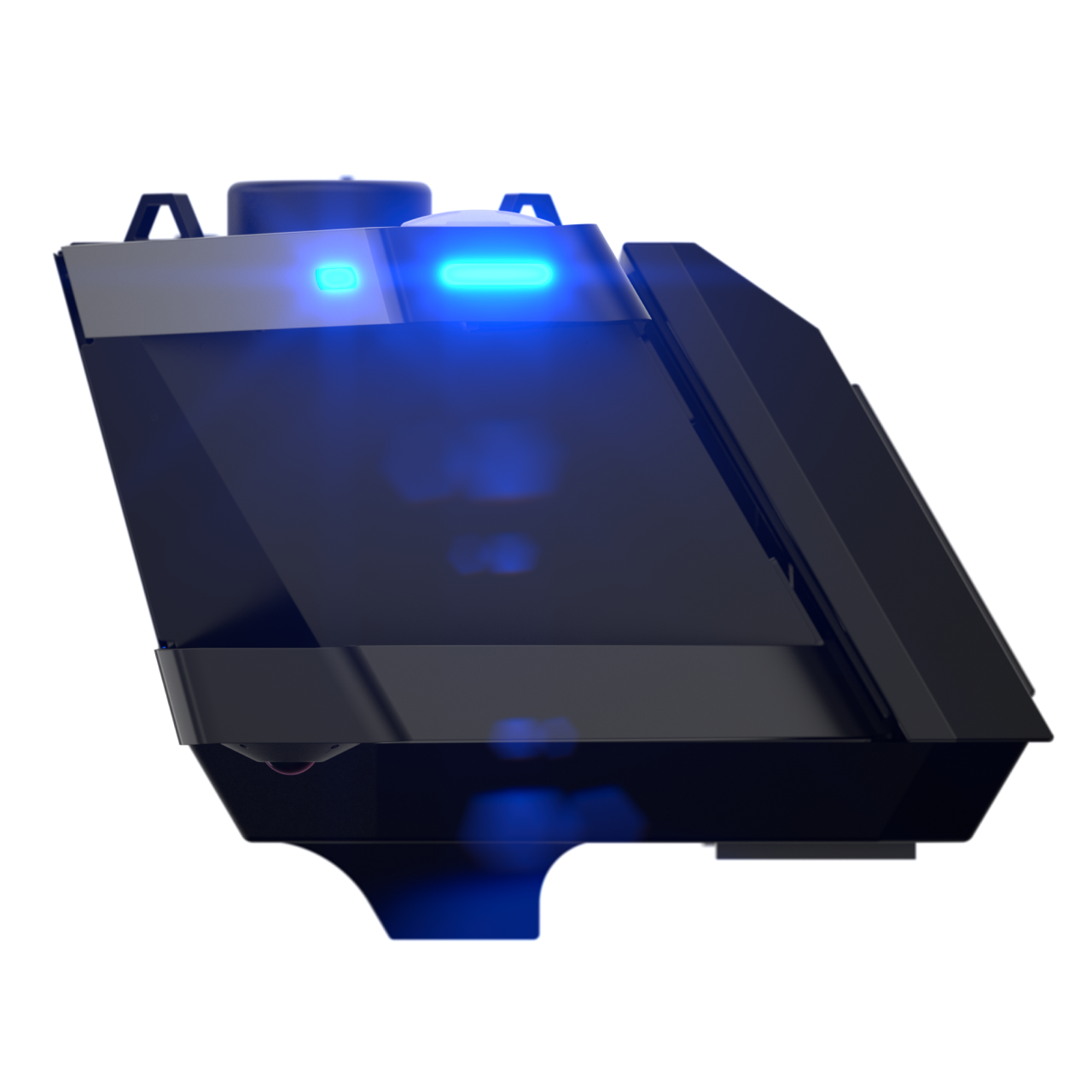

Advanced Robotics

With intelligent sensor fusion, AI-powered vision systems, real-time production data, and edge computing, the most advanced construction autonomy is now available for piling on solar farms.

Safer Results. Safer Work.

Make jobsites safer with autonomous tools. An 8-Layer Safety System keeps workers safe around the robot. With autonomous piling, workers can avoid the extreme weather, sound, struck-by, and caught in-between accidents common with manual operation.

Tight Tolerances

Nothing compares to the accuracy and precision of a robot. Achieve results that repeat themselves from the first pile to the very last to help enable issue-free tracker installation.

Lower Costs

Drive more, spend less. Robotics lower installation and labor costs. The RPD 35 frees up valuable labor to focus on critical tasks letting solar developers optimize piling costs to stay competitive and win the market.

Maximum Uptime

Unlock a new way of running your business. Robots reduce schedule uncertainty, limit rework, and operate with little interruption, which maximizes equipment utilization and uptime to create productivity unseen with traditional means and methods.

Pile on the Features

Up to 5× Faster

The RPD 35 is a field-proven force multiplier that works up to five times faster than a traditional pile driver. Reduce cycle times and boost productivity with the most advanced pile driver on the market.

Millimeter Accuracy

Achieve millimeter accuracy with state-of-the-art RTK GPS, IMUs, and sensors. Unlock consistent piling capabilities that minimize time spent on inspection and rework.

Refusal Detection

Stay on track even when piles hit refusal. The RPD 35 will automatically flag piles that exceed the refusal threshold and continue on to the next pile in the sequence.

Take Out Shakeout

Eliminate pile distribution with a unique basket design. The RPD 35 can carry up to 224 piles on each run. Conventional methods of shakeout don’t stand a chance.

Pile Compatibility

Minimize site preparation and grading with an adaptable system that can support almost any foundation design. The RPD 35 can install piles up to 21 feet long and 400 pounds in weight, as well as both W6 and W8 cross sections.

Automatic As-Builts

Consolidate as-built documentation into a single source of truth. The RPD 35 creates highly-accurate drawings automatically. Access, view, and export your files for seamless handoff.

No Pressure

Work in muddy weather with industry-leading ground pressure of 11 psi. The RPD 35 offers ground clearance of 1.6 feet, ensuring you never miss work for a rainy day.

Robotic Consistency

Reliably install within stringent tolerances without missing a beat. Using the RPD 35 reduces rework and minimizes damage to pile heads to boost your productivity and lower your costs.

Safe and Sound

Install piles out of earshot. Operators can monitor the RPD 35 from a distance, which limits harmful noise exposure common in traditional piling methods.

Mix and Match

Install different types of piles all from one basket. The RPD 35 can install piles with varying lengths and flange widths in one cycle without need to stop, reload, and restart.